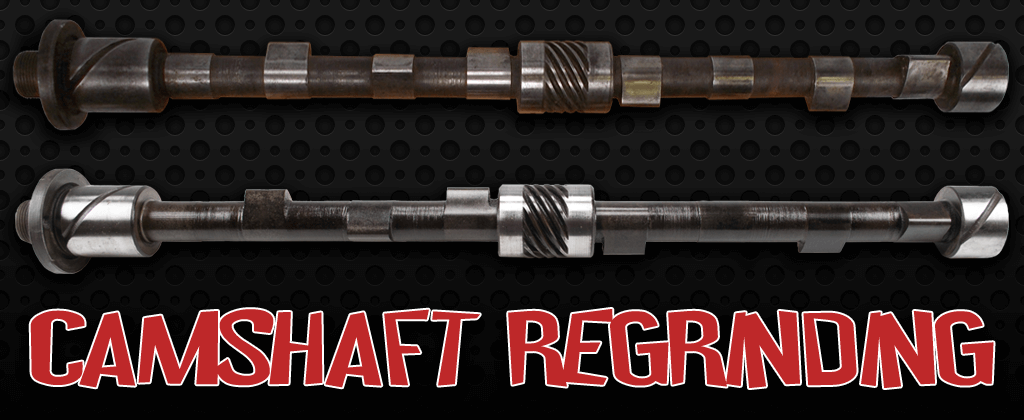

CamShaft Regrinding

Camshafts control the opening, closing, lift and duration of valves. This means precision is essential to engine power, pick-up and fuel economy. Wear on your camshaft will cause excessive valve noises, engine roughness when idling, a lack of power and erratic operation. Maximum horsepower and other engine benefits depend upon camshaft precision - because they depend upon valve timing. Regrinding is the only method of restoring this precision when wear occurs. Regrinding restores horsepower and mechanical harmony, provides smoother idling, quieter valve action, proper valve timing, more vacuum and quicker acceleration.

It is highly recommended whenever you rebuild your engine that you replace or regrind your camshaft. Whenever you replace or regrind your camshaft you should also replace your lifters, because using improperly surfaced or used lifters can cause premature wear of your new or reground camshaft. Here is more information about resurfacing your lifters.

Whenever rebuilding your engine or replacing your camshaft and lifters, Egge recommends following proper engine break in procedures and using an oil designed with enough zinc for flat lifters and cams such as Torco TBO Premium Break-in Oil and using a zinc additive like Torco ZEP with your normal motor oil.

Egge can regrind your camshaft with a stock or mild-performance grind for most applications. We also carry many new and reground camshafts with core exchange.

Contact us at 800-866-3443 or info@egge.com to send in your water pump for remanufacturing.